Trillium Compact OBS

Summary

The Trillium Compact Ocean Bottom Seismometer is available with a titanium enclosure for deployments to 6000m in depth, or with an aluminum enclosure for shallow-water deployments to 1800m.

Its low-profile design minimizes ocean current induced noise effect and it boasts ultra-low power consumption of just 180mw.

It offers a primary analogue connection and a second, separate digital connection for final system verification prior to deploying the OBS overboard, without disturbing the primary connection.

The internal state-of-health data provides valuable information on leveling cycles, leveling corrections and case orientation, providing a powerful data set for optimizing deployment techniques.

The precise, kinematic 360°gimbal auto-levels from any orientation ensuring successful deployment and implementation. Leveling control is internal and can be scheduled or "as necessary" based on instrument tilt and mass position values.

Nanometrics' Trillium Compact OBS might be right for you if:

- You want the exceptional dynamic range and low noise floor of a land-based Trillium Compact

- You're looking for a high-performance, 120 second broadband seismometer that integrates with existing short-period or mid-band infrastructure (platforms, power systems and digitizers)

- You want ultra-low power consumption to reduce battery costs

- You'd like to minimize the effects of ocean current-induced noise

- You want the ease of automatic leveling from any orientation

Specifications

Specifications are subject to change without notice.

TECHNOLOGY |

|

|

Topology:

Feedback:

Mass Centering:

|

Symmetric triaxial

Force balance with capacitive transducer

Not required

|

PERFORMANCE |

|

|

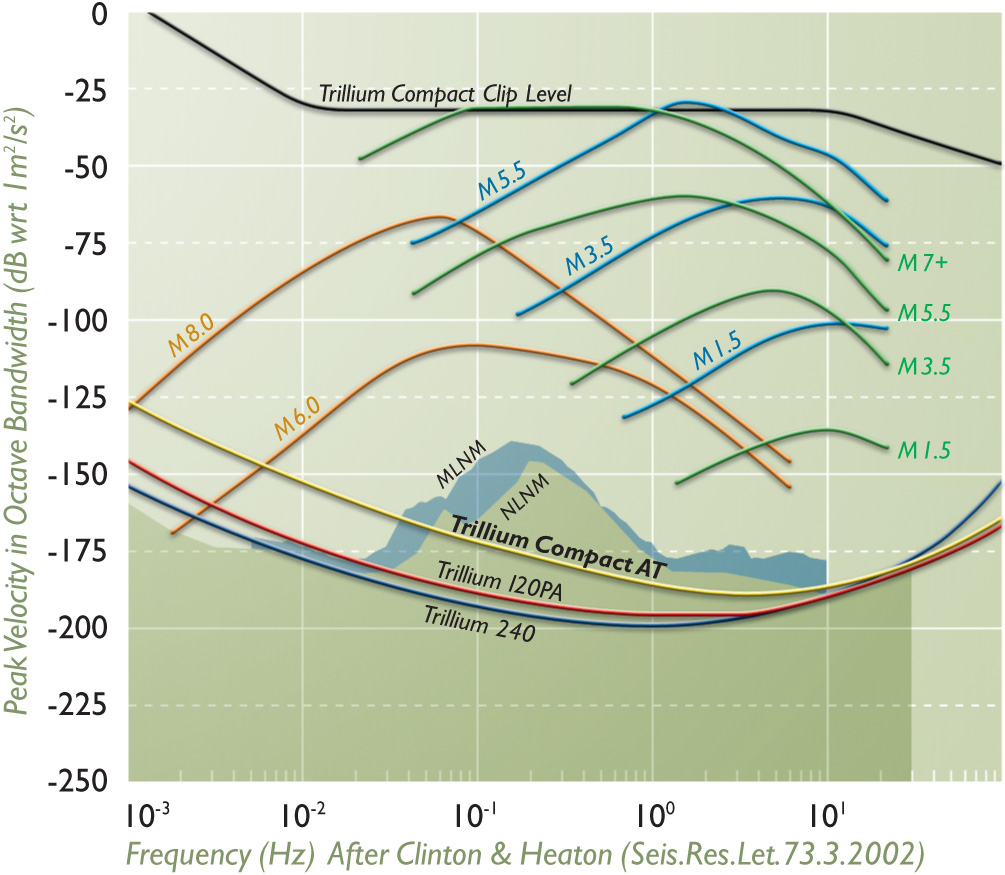

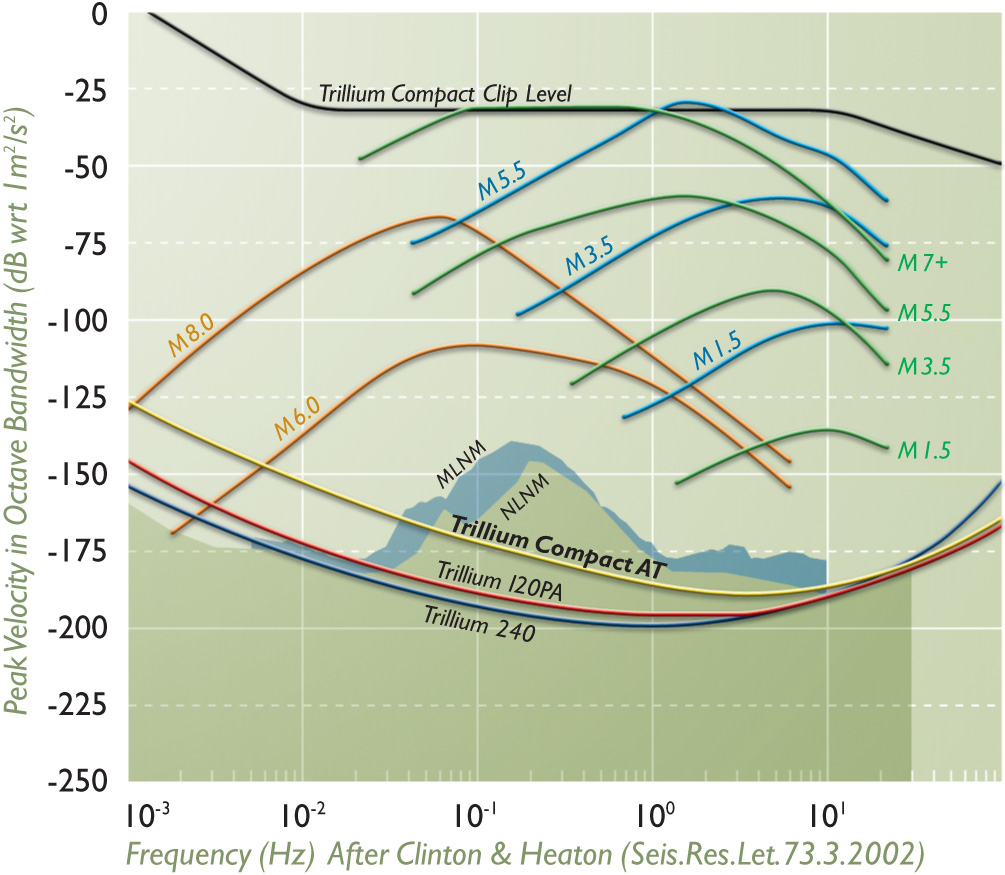

Self-noise:

Sensitivity:

Off-axis Sensitivity:

Bandwidth:

Transfer Function:

Clip Level:

Parasitic Resonances:

Operational Tilt Range:

|

See graph

750 V·s/m nominal ±0.5% precision

±0.5 %

-3dB points at 120 s and 100 Hz

Lower corner poles within ±0.5% of nominal provided

High-frequency response within 1dB of nominal

No peak in response at high frequency

26 mm/s from 0.1 Hz to 10 Hz

None below 100 Hz

±2.5° without re-leveling

|

LEVELING AND ORIENTATION |

|

|

Technology:

Clamping:

Range:

Accuracy:

Leveling Initiation:

Magnetometer:

Case and Sensor

Inclinometers

|

Dual degree-of-freedom motorized gimbals

Jam-free mechanism

Kinematic design preserves full seismometer performance

Active, sequenced by gimbals processor

>±180° relative to upright case

Levels to within ±0.5° of true vertical

Some or all of:

> configurable delay after power on

> configurable three-stage periodic

> delay intervals configurable from seconds to months

Scheduled leveling checks do not disturb seismic data recording when sensor is level

3-component, mounted on and leveled with seismometer

Tilt orientation of vessel and sensor recorded throughout

deployment

|

DIGITAL INTERFACE |

|

|

Type:

Leveling:

Mode Selection:

Calibration Channel Selection:

Firmware:

|

RS-232 compatible Serial Line Internet Protocol (SLIP)

On board Web Server, standard HTTP

Initiate immediate leveling

Automatic cycle mode (post power-on, periodic, as-needed)

Automatic cycle parameter selection (delay with interval time selection, maximum number of attempts): XYZ/UVW

Short Period/Long period

Off, enable all, U, V, or W

Update Firmware

|

DATA OUTPUTS |

|

|

On Request:

Leveling Log:

State-of-Health Log:

|

Independent mass position values

Instrument temperature

SOH

Magnetometer readings

Case orientation (with respect to vertical)

Seismometer orientation (with respect to vertical)

Download state-of-health (SOH) log

Erase SOH log

Download custom information

Factory sensitivity and sensor response data

User calibration data (poles and zeros)

Instrument serial number and firmware revision

Every leveling event is logged in non-volatile memory

Full before-and-after state-of-health is logged

Scheduled interval logging of SOH, including:

> Time from power-on

> Seismometer mass positions

> Vessel and seismometer orientations

> Magnetometer readings

> Temperature

Capacity for more >2 years of twice daily level checks and SOH logging

|

PHYSICAL |

|

|

6000m Variant

Enclosure:

Diameter:

Height:

Weight:

1800m Variant

Enclosure:

Diameter:

Height:

Weight: |

Titanium, non-painted cylinder

All connectors on top end cap

End caps removable for O-ring servicing

Dual O-ring seals on each end cap

158 mm

257 mm, not including connectors

11.96 kg on land, 6.66 kg in water

Aluminum, anodized, enamel painted cylinder

All connectors on top end cap

End caps removable for O-ring servicing

Dual O-ring seals on end cap

170 mm

258 mm, not including connectors

8.7 kg on land, 3.01 kg in water

|

CONNECTORS |

|

|

Main Connector:

Secondary Connector:

(Auxiliary/Diagnostic):

Vacuum/Pressure Port:

|

12-pin female, VSK-12-BCL rubber-molded glass epoxy

40V peak-to-peak differential seismic signal plus ground (3 channels)

Serial RS-232 port (Rx, Tx, GND)

Calibration voltage input

Power input and return

4-pin female, VSG-4-BCL rubber-molded glass epoxy

Serial RS-232 port

Auxiliary control input

¼” male quick disconnect with shutoff

Vent for evacuation and servicing |

POWER |

|

|

Supply Voltage:

Power Consumption:

Protection:

|

9 to 29 VDC isolated

<180 mW typical (leveled, quiescent)

Reverse-voltage and over-voltage protected

Self-resetting over-current protection

Unit can be powered on for descent and ascent

|

ENVIRONMENTAL |

|

|

Operating Temperature:

Storage Temperature

Shock:

Transportation:

Magnetic:

|

-20ºC to +60ºC

-40ºC to +70ºC

100g half sine, 5 ms without damage, 6 axes

No seismometer mass lock required prior to deployment and through full experiment cycle

Insensitive to natural variations of the Earth’s magnetic field

|

Performance